How Much Does It Cost to Get Started 3D Printing?

3D printing has revolutionized the manufacturing industry, allowing individuals and businesses to create three-dimensional objects from digital designs. If you’re interested in venturing into the world of 3D printing, you might be wondering about the cost involved in getting started. In this article, we will break down the key components and expenses to help you understand the budget required to embark on your 3D printing journey.

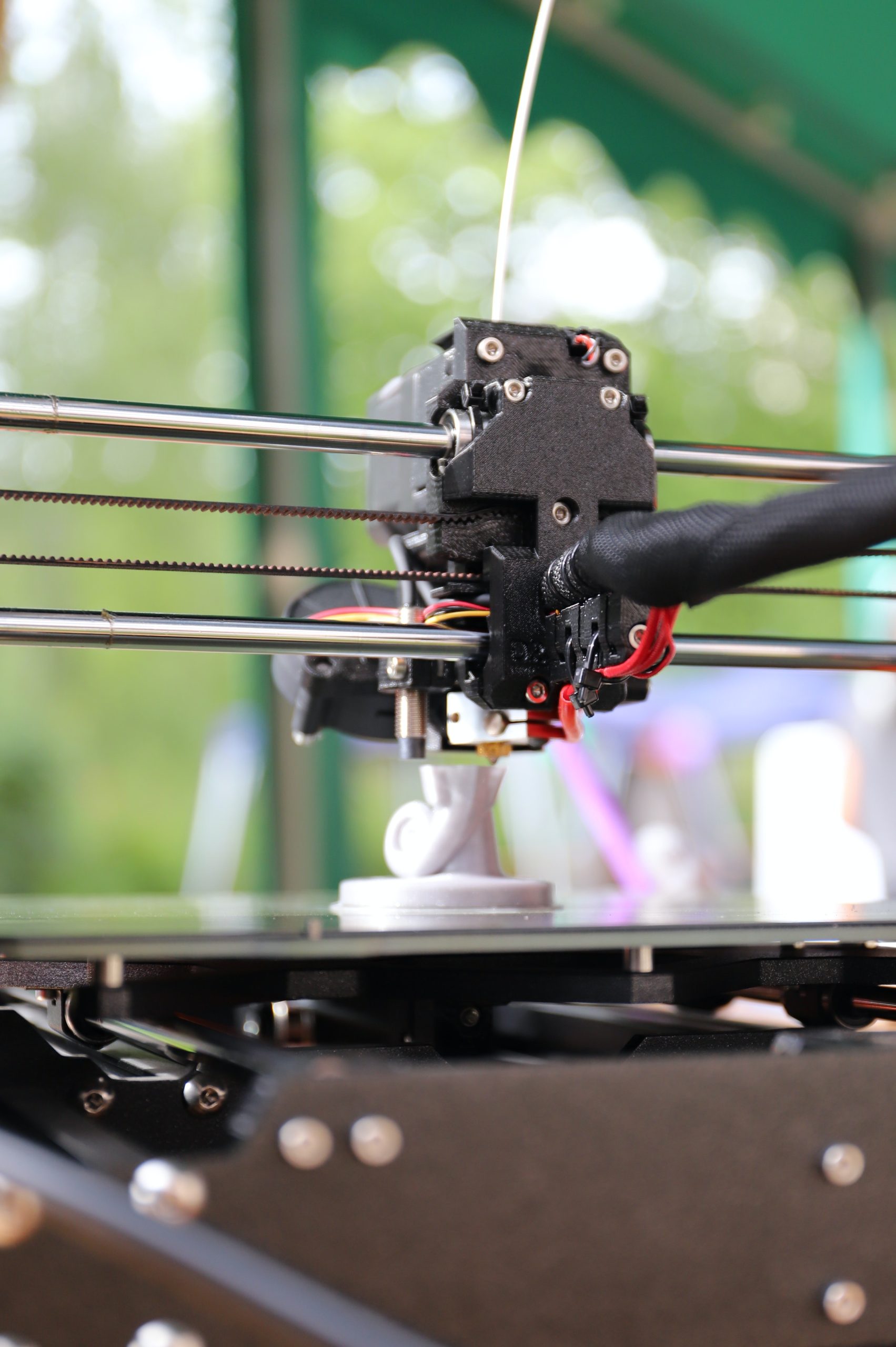

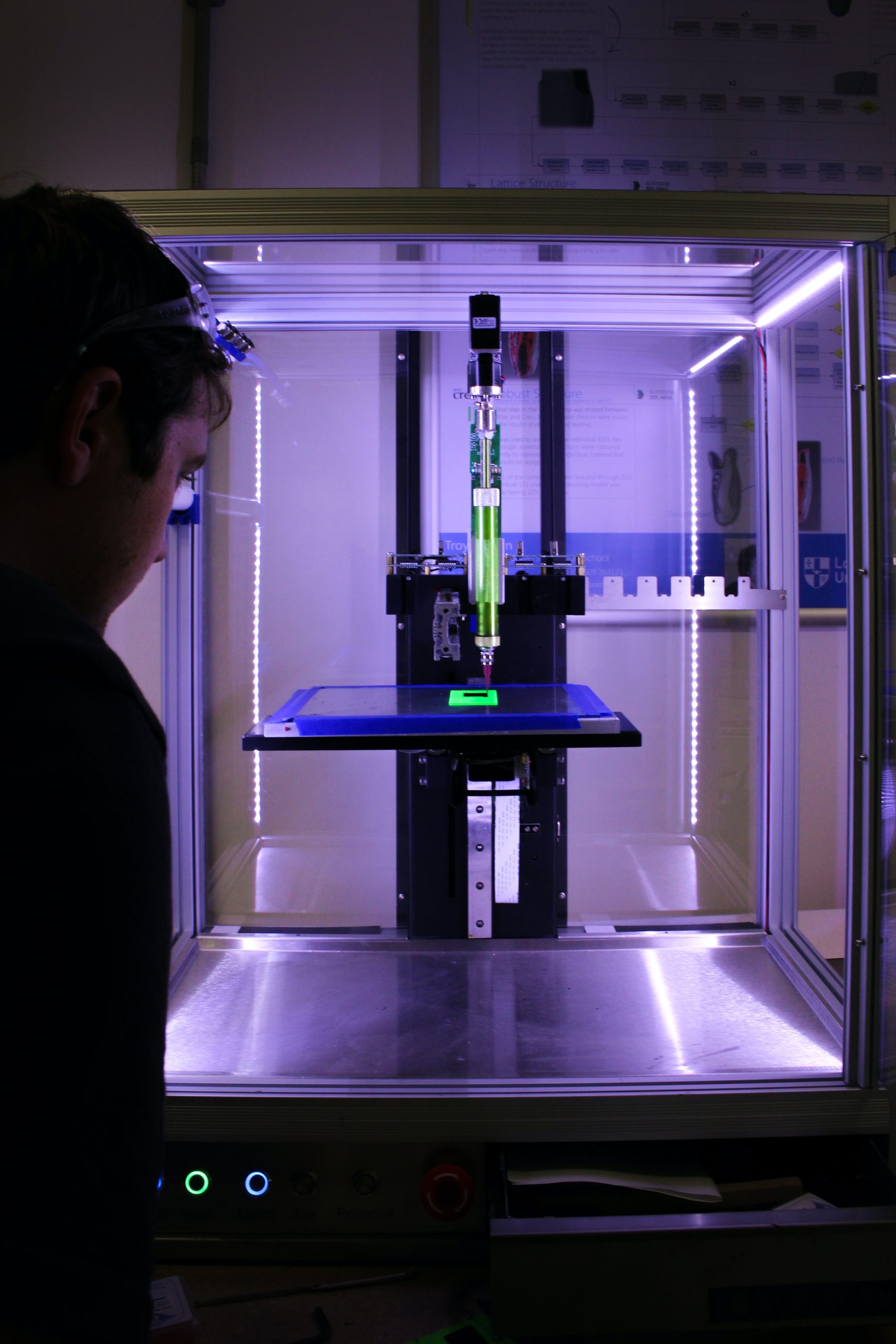

1. 3D Printer

The most significant expense when starting 3D printing is the cost of the 3D printer itself. The price range for 3D printers can vary significantly, starting from a few hundred dollars for entry-level consumer models to several thousand dollars for professional-grade machines. The price variation depends on factors such as print quality, build volume, printing speed, and additional features. Determine your specific requirements and budget constraints to choose a 3D printer that suits your needs.

2. Filaments

The filament is the material used in 3D printing, typically made of thermoplastics like PLA (Polylactic Acid) or ABS (Acrylonitrile Butadiene Styrene). The cost of filaments can vary based on the type, color, and brand. On average, a spool of filament (typically weighing around 1 kilogram) can cost anywhere from $20 to $50, although prices may vary. The amount of filament consumed depends on the size and complexity of your prints.

3. Print Bed Adhesion Aids

To ensure successful printing, you may need additional materials to help with print bed adhesion. This includes products like adhesive sprays, tapes, or specialized build surfaces. The cost of these adhesion aids is relatively low, usually ranging from $5 to $20, depending on the specific product and brand.

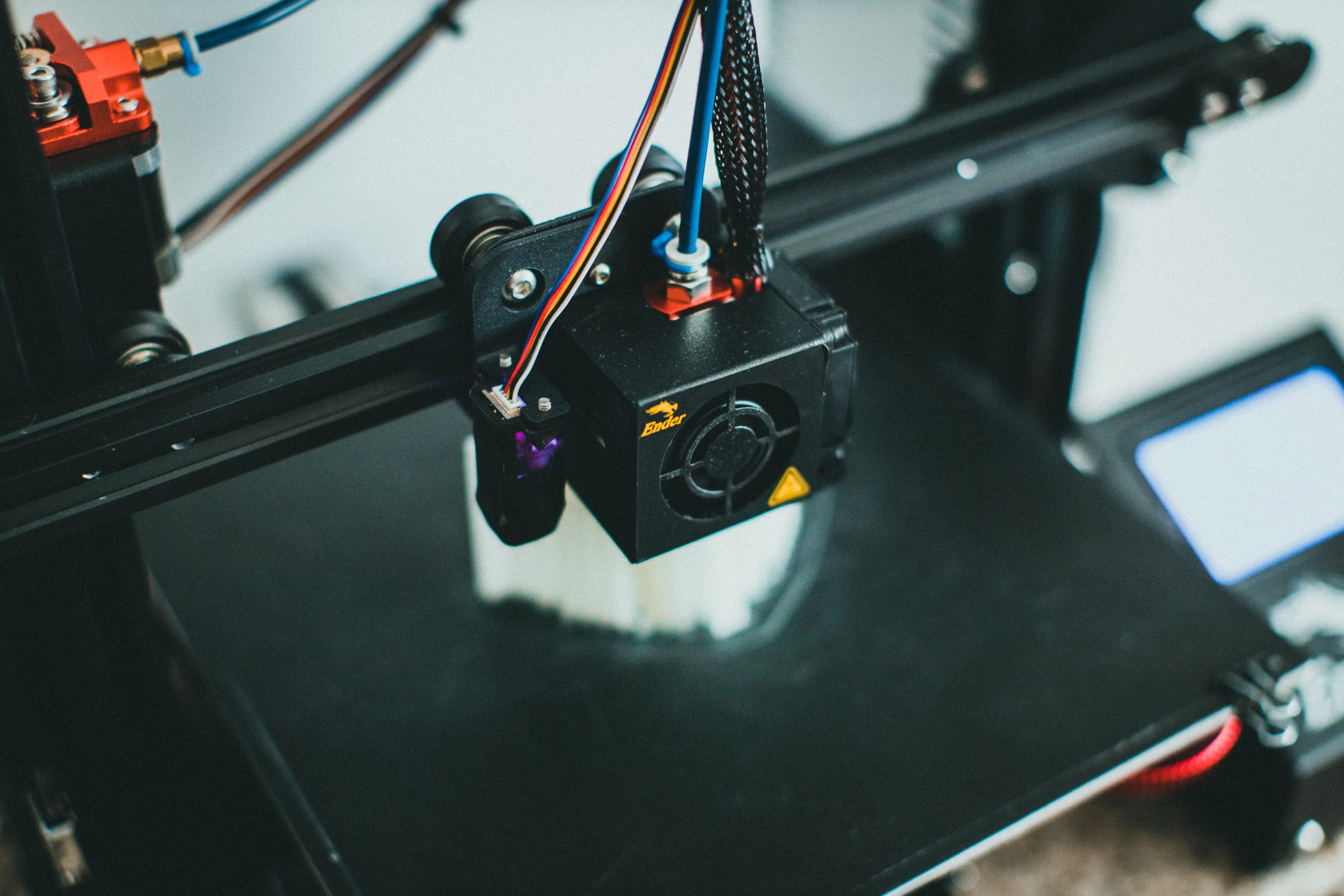

4. Maintenance and Upgrades

Like any piece of machinery, 3D printers require maintenance and occasional upgrades. This can include cleaning supplies, lubricants, replacement parts (such as nozzles or belts), or enhancements to improve printing quality or speed. The maintenance and upgrade costs will vary depending on the printer model and the frequency of use. It is advisable to set aside a small budget for these ongoing expenses.

5. Design Software

To create or customize 3D models for printing, you may need design software. Fortunately, there are several free or low-cost options available, such as TinkerCAD, Fusion 360, or Blender. These software tools offer a range of capabilities for beginners and professionals alike. However, if you require more advanced features, you might consider investing in commercial design software, which can cost several hundred dollars per year.

6. Post-Processing Tools

Once your 3D prints are complete, you may need post-processing tools to refine the final product. This can include sanding tools, primers, paints, or specialized equipment for smoothing printed surfaces. The cost of post-processing tools will depend on the complexity of your projects and the level of finishing you desire.

7. Electricity and Consumables

It’s important to consider the ongoing operational costs associated with 3D printing, such as electricity consumption and general consumables. While these costs may seem minimal, they can add up over time. It is advisable to research the power consumption of your 3D printer model and estimate the associated electricity costs. Additionally, consider the need for general consumables like cleaning wipes, brushes, or storage containers.

Getting started with 3D printing involves an initial investment, primarily in a 3D printer and filaments. The overall cost will depend on the quality and features you require. Additionally, you should budget for maintenance and upgrades, design software, post-processing tools, and ongoing operational expenses. By considering these factors and setting a budget, you can embark on your 3D printing journey with confidence. Remember, the cost of 3D printing is not limited to the initial investment but also includes the ongoing expenses associated with materials, maintenance, and upgrades.